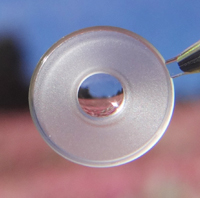

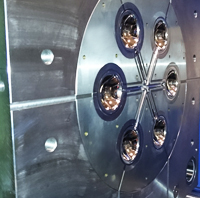

Injection Mold for Micro Lens on Smartphones

These days, the camera modules in the smartphones are requiring higher and higher pixelation, and the plastic lenses used in these modules must be able to accommodate 20M class pixel counts. Every lens manufacturer is putting their effort into developing the precision required for such lenses.

Our Micro Lens Mold has been selected by many lens manufacturers for its unique construction which brings stable production of plastic lens with excellent precision in terms of decentering, comatic aberration, astigmatism, and spherical aberration, etc.

-High precision.

-Easily adjustable structure.

-Stability in mass production.

Our Micro Lens Mold has been selected by many lens manufacturers for its unique construction which brings stable production of plastic lens with excellent precision in terms of decentering, comatic aberration, astigmatism, and spherical aberration, etc.

-High precision.

-Easily adjustable structure.

-Stability in mass production.

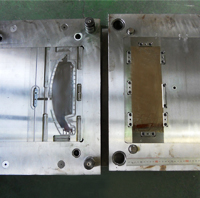

Injection Mold for Light Guide Panel in Arcade Game Machines

To improve the brightness of the illumination units in arcade game machines, high replication property of the light guide panel is essential. To address this requirement, we have prepared temperature control circuits filled with our technical expertise, and have introduce them into our mold design. These circuits also have proven to be effective in reducing warp and internal stress in the produced light guide panels.

With Craft one's unique hot runner system, we have succeeded in materializing shorter sprue bush, downsized mold, and reduced price of the mold.

-Unique temperature control circuit.

-Good replication property.

-Lower warpage.

-Reduced internal stress.

-Unique hot runner system.

-Reduced material cost.

-Faster molding cycle.

-Downsizing molding machine.

-Unique temperature control circuit.

-Good replication property.

-Lower warpage.

-Reduced internal stress.

-Unique hot runner system.

-Reduced material cost.

-Faster molding cycle.

-Downsizing molding machine.

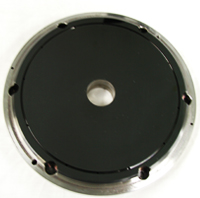

Injection Mold for Optical Disc

We undertake maintenance work on molds producing optical discs such as BD, DVD, and CD that have worn down in mass production. We first check the condition of the mold carefully. And then by either repairing or reproducing the parts like mirror plate, sprue bush and cut punch, we refurbish the mold back nearly into its brand new condition.

We also offer help in remodeling of old molds to those customers who want to improve usability of their current molds, or adopt our know-hows into them.

-Repairing of parts like mirror plate, sprue bush, and cut punch.

-Fabrication of parts like mirror plate, sprue bush, and cut punch.

-Modification of optical disc molds.

We also offer help in remodeling of old molds to those customers who want to improve usability of their current molds, or adopt our know-hows into them.

-Repairing of parts like mirror plate, sprue bush, and cut punch.

-Fabrication of parts like mirror plate, sprue bush, and cut punch.

-Modification of optical disc molds.

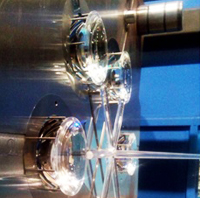

Injection Mold for PES Lens

With LED head lamps getting brighter and brighter, PES head lamps are getting more attention these days. Luminance and rectilinear advancing property of PES head lamp can be improved by adopting aspherical lens. Its performance depends on the precision of the lens, i.e., the precision of the PES lens.

Craft one has been providing high precision PES lens molds, to which we poured our abundant experiences in optical mold technologies.

Craft one has been providing high precision PES lens molds, to which we poured our abundant experiences in optical mold technologies.

Injection Mold for Head-up Display

Head-up Display(HUD)is a system to project images on a transparent panel set in front of the vehicle’s driver. Several car manufacturers have been adopted the system, and some of their cars have been on sale with the system on-board.

Craft one’s head-up display molds help materialize their system through the mold construction fully loaded with our expertise to achieve better surface accuracy, and handlapping techniques producing mirror finish at nanometer level.

Craft one’s head-up display molds help materialize their system through the mold construction fully loaded with our expertise to achieve better surface accuracy, and handlapping techniques producing mirror finish at nanometer level.